SH Foodie Scale up Centre

At SH Foodie, we have our very own Beverage Pilot Plant Facility where we can produce cans and bottles of sparkling or still, soft or alcoholic drinks with methods that mirror factory processes. We are also able to fill pouches with liquids or powders.

These are ideal for you to carry out market or product testing or for presentations with Investors or Retailers.

Wait! Have You Considered...

Before you commit to having your beverages produced at your chosen manufacturer, a Pilot / Scale up trial can be extremely beneficial, giving you and your manufacturer the confidence that your product can be made effectively and efficiently.

It also gives you the opportunity to refine your beverage formulation before making a larger quantity. It goes without saying that it is important to ensure that the taste, and quality of the beverage meets consumer expectations.

Trial runs can also help to fine tune the production process, gain valuable product targets and tolerances for confirmation of quality control measures that will ensure consistency and safety of your product once it moves to full scale production.

Many commercial contract manufacturers prefer onboarding customers who have products that have robust recipes with accompanying processing and technical information as this helps them to be sure that they can make your product effectively and to the desired costs.

Scale-Up Trials with SH Foodie are the Ideal Steppingstone

Before moving to full scale production and serve as a critical step in the product development and manufacturing process, ultimately increasing the chances of success in the market.

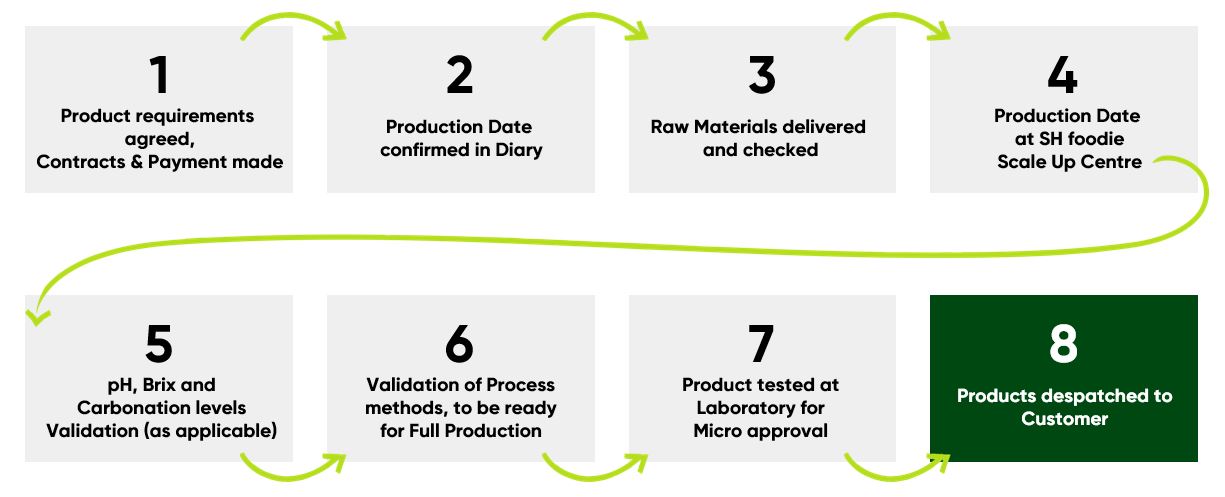

Scale-Up/Small Scale Production Process Flow

What We Offer...

- Low minimum order quantities - from 150-1500 cans, bottles or pouches per flavour variant can be made for you in a range of sizes from 150ml to 500ml and everything in between. Sleek and Standard.

- Controlled mixing and processing using our bespoke equipment that has been especially designed to mirror Factory production methods.

- Pasteurisation to ensure shelf life and food safety are considered.

- Quality testing to make sure excellent and consistent standards are achieved.

- Wrap-around Label application onto cans.

- Helping you move seamlessly from Development through to Production.

- Gives you more confidence that your product is going to be a success!

What's Included:

- Cans / Bottles / Pouches / Lids and outer cases, quality testing and laboratory microbiological clearance plus labour costs.

Additional Extras:

- Ingredients can be ordered if required or Customers can arrange for deliveries of raw materials, if preferred.

- Nutritional & Shelf-Life testing can be arranged at a UKAS accredited laboratory, if required.

- Label design and printing, if required we can provide details.

Let's talk about your product.

We would love to hold a free 30 minute call to discuss your exciting idea.